Mounting Guide: Kutzall Shaping Discs & Dish Wheels

Feb 10, 2015

You want nothing less than the full performance benefits from an amazing product like a Kutzall wheel! To assure that you get the best results, we've developed this Mounting Guide to assist you.

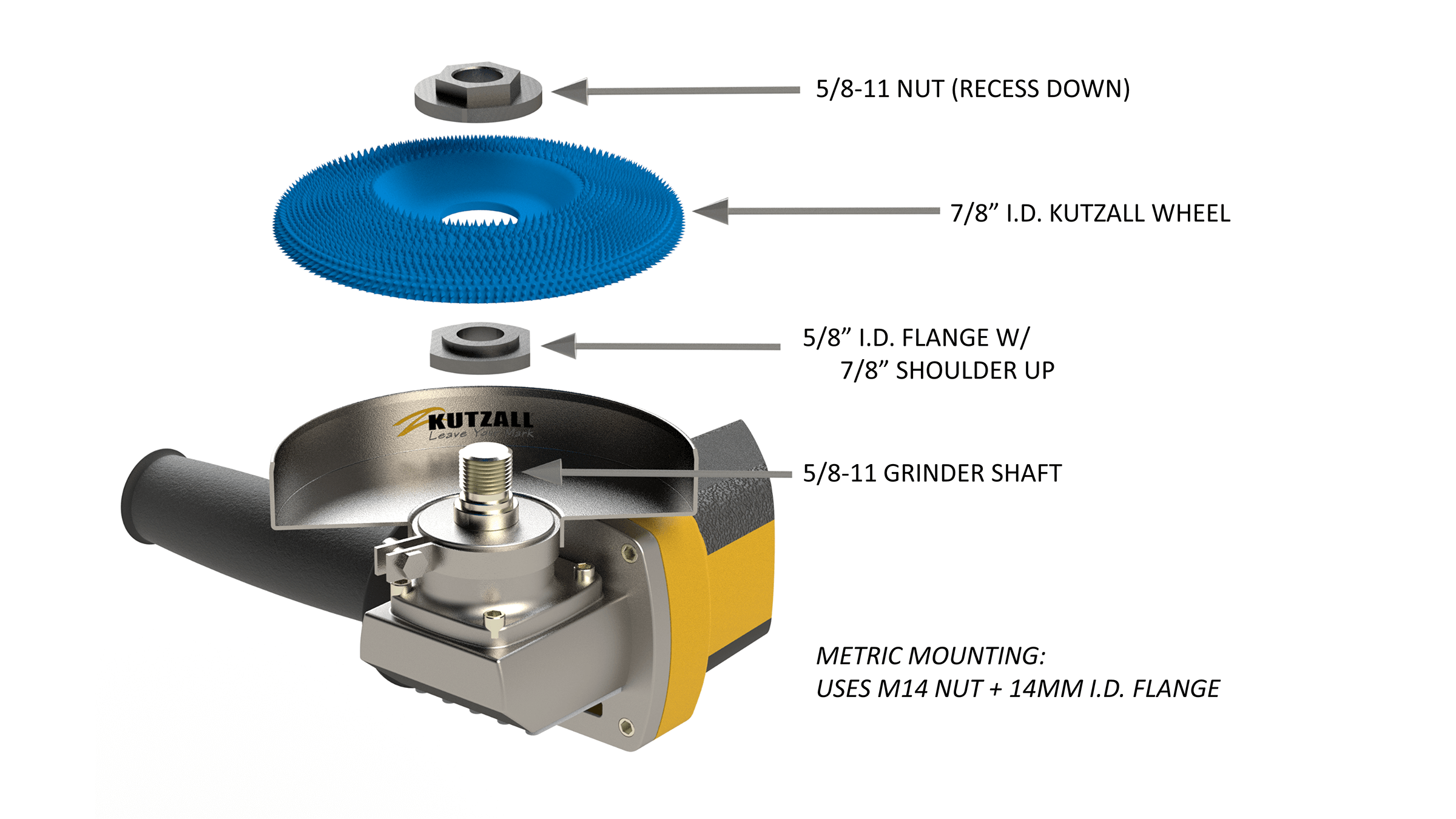

Standard Kutzall Mounting: 5/8-11 and M14 Shafts

Kutzall Shaping Wheels feature a 7/8" I.D. and are intended to mount on standard electric or pneumatic angle grinders with a 5/8-11 or M14 threaded shaft. The wheels mount on the grinder's shouldered backside or bottom flange (stepped bushing), which has a 7/8" (22mm) O.D. mounting shoulder to accommodate most modern grinder accessories. If for some reason you do not presently have the back flange to fit your grinder, you often can obtain one online, using a parts list for your grinder. As a quick and easy alternative, please see our Universal Flange listing.

Proper mounting of a Kutzall wheel using a shouldered flange assures that the wheel will spin as straight and true as possible. This makes working with the tool smoother and more comfortable, while assuring that you use the entire surface of the wheel equally. Below is a photo showing a typical Kutzall mounting arrangement.

Tip: Shouldered flanges may be found on the parts list for your grinder on the manufacturer's website.

Click here to view the image in a new window

Note that outside or 'top' spanner nuts on most angle grinders are often reversible, with a 7/8" accessory shoulder on one side, and a 7/8" relief recess on the other side. The projecting shoulder on the nut faces away from the wheel when clamping a 'thin' accessory like a Kutzall Wheel. The projecting shoulder on the bottom or back-side flange, however, always faces up towards the wheel, to center it. The photo above shows the aftermarket hexagonal Universal Nut, which we offer as a superior alternative to the standard spanner nut.

While correct wheel-to-shaft fitment is critical to ensuring proper wheel performance, checking the guard compatibility is also an important step. Please click here to review.

Other Grinder Fitments

Older grinders often had a smaller 3/8-24 or 10mm shaft, with a flanged shoulder sized for a 5/8" accessory I.D. If you have an older grinder with the 3/8-24 or 10mm shaft size, and want to use current 7/8" I.D. Kutzall wheels, you might be able to purchase an adapter to convert your shaft so it will fit a typical 5/8-11 I.D. nut and flange set with a 7/8" accessory shoulder. With such an adapter, you could then likely use our Universal Nut and Universal Flange, to secure your Kutzall Shaping Wheel.

2 comments

Chuck,

We are very sorry that you had to open up the I.D. on your Kutzall disc. Because the Kutzall discs are rather heavy, we are extremely cautious about not making the I.D. size larger than absolutely necessary. At the 10,000 to 12,000 RPM typically generated by electric angle grinders, any sloppiness in the I.D.-to-shaft fitment results in run-out, which can translate to a lot of unpleasant vibration for the operator and a deterioration in finish quality on the work-piece. Because we make the discs knowing they will be used on a wide variety of grinders, from many manufactures, all with significantly different tolerances for their shoulder nut or flange shoulder dimension, we aim our tolerances for the low end on I.D. size. Again, we apologize for the inconvenience to you. We realize it’s a bit of a pain when someone like you has to fit the wheel up, but you probably have the lowest-possible-vibration setup going as a result. Sometimes nothing beats a hand-fitment!

I had to scrap paint from the disk and slightly file the inner of the hole to get a good fit against the 7/8 rimmed piece. You might want to mention that possibility to future buyers.